WD-40 Specialist Silicone Lubricant: The Ultimate Solution for Precision Maintenance Across Automotive, Industrial, and Household Applications Silicone Lubricant

In a world where mechanical reliability dictates performance, safety, and longevity—every component matters. From the high-stakes precision of MotoGP racing to the daily demands of family vehicles, industrial machinery, and home appliances, the integrity of moving parts hinges on one critical factor: proper lubrication. Enter WD-40 Specialist Silicone Lubricant—a meticulously engineered formulation that transcends conventional expectations, delivering unmatched protection, silence, and durability across an extraordinary spectrum of applications.

Born from a legacy of innovation spanning over seven decades, WD-40 has evolved from a humble aerospace-derived formula into a global benchmark for maintenance excellence. Since its inception in 1953—originally developed for the U.S. aerospace industry—and its commercial launch in 1973, the brand has become synonymous with trust, efficacy, and technical mastery. Today, WD-40 Specialist Silicone Lubricant stands as the pinnacle of this heritage: a high-performance, non-greasy, non-drip silicone-based spray designed not merely to lubricate, but to preserve, restore, and enhance functionality across diverse mechanical systems.

Engineered for Excellence: Core Technical Advantages

At the heart of WD-40 Specialist Silicone Lubricant lies a proprietary silicone polymer matrix, carefully balanced to deliver four essential functional pillars:

1. Superior Lubrication Without Residue

Unlike petroleum-based greases or oils that attract dust, gum up under heat, or migrate unpredictably, this silicone formulation provides long-lasting, dry-film lubrication. It adheres tenaciously to surfaces without dripping, running, or leaving sticky residues—ensuring consistent performance even in vertical or inverted orientations. This property is indispensable for delicate mechanisms like door seals, window regulators, and throttle linkages, where excess lubricant could contaminate adjacent components (e.g., paint, upholstery, or electrical contacts).

2. Exceptional Resistance to Environmental Degradation

Silicone’s inherent molecular stability grants this product outstanding resistance to UV radiation, ozone, moisture, and extreme temperatures ranging from -50°C to +200°C. This makes it ideal for outdoor-exposed components—such as motorcycle drive chains, trailer hitch pins, or garden equipment—where conventional lubricants would oxidize, harden, or wash away within weeks. Crucially, it does not swell or degrade most common elastomers (rubber, EPDM, nitrile), preserving seal integrity while eliminating squeaks and binding.

3. Non-Conductive & Safe for Electrical Systems

With a dielectric strength exceeding 15 kV/mm, WD-40 Specialist Silicone Lubricant is fully compatible with low-voltage electrical assemblies—including ignition systems, sensor housings, and switch mechanisms—without risk of short circuits or arcing. Its rapid evaporation leaves behind only a thin, insulating film that repels moisture and prevents corrosion on metal contacts, significantly extending service life in humid or corrosive environments.

4. Dual-Action Protection: Lubrication + Preservation

Beyond reducing friction, the formulation contains anti-oxidant and anti-corrosion additives that form a hydrophobic barrier against moisture ingress and atmospheric pollutants. This dual-action mechanism actively combats premature aging of rubber, plastic, and coated metals—preventing cracking, stiffening, and loss of elasticity in critical sealing elements such as engine gaskets, HVAC duct seals, and hydraulic cylinder boots.

Precision Applications Across Domains

Automotive Excellence: From Race Tracks to Daily Commutes

The WD-40 Specialist Silicone Lubricant has earned its stripes on the world’s most demanding circuits—celebrating its association with the Ducati Corse MotoGP team’s 2023 Constructor Championship victory. But its value extends far beyond professional motorsport:

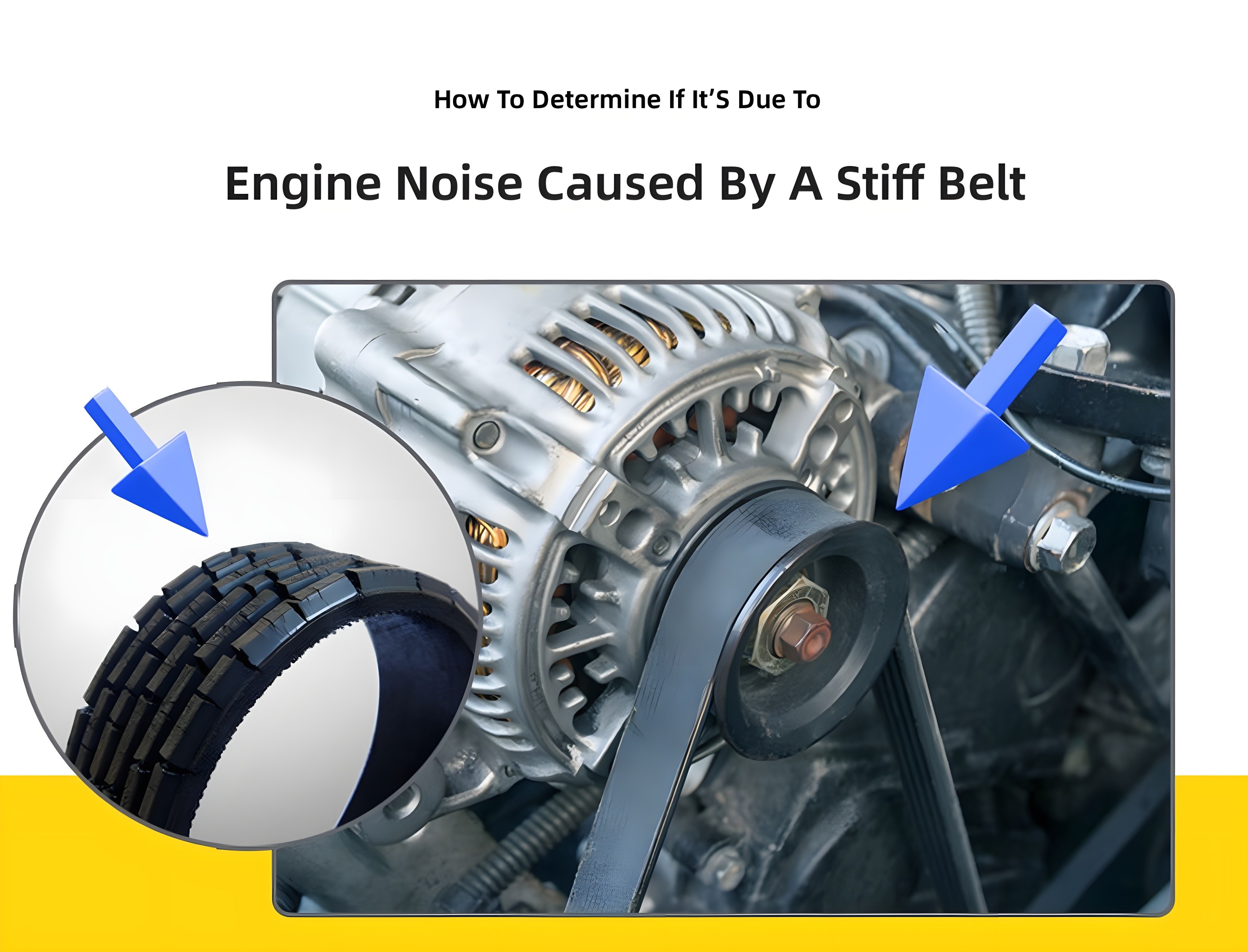

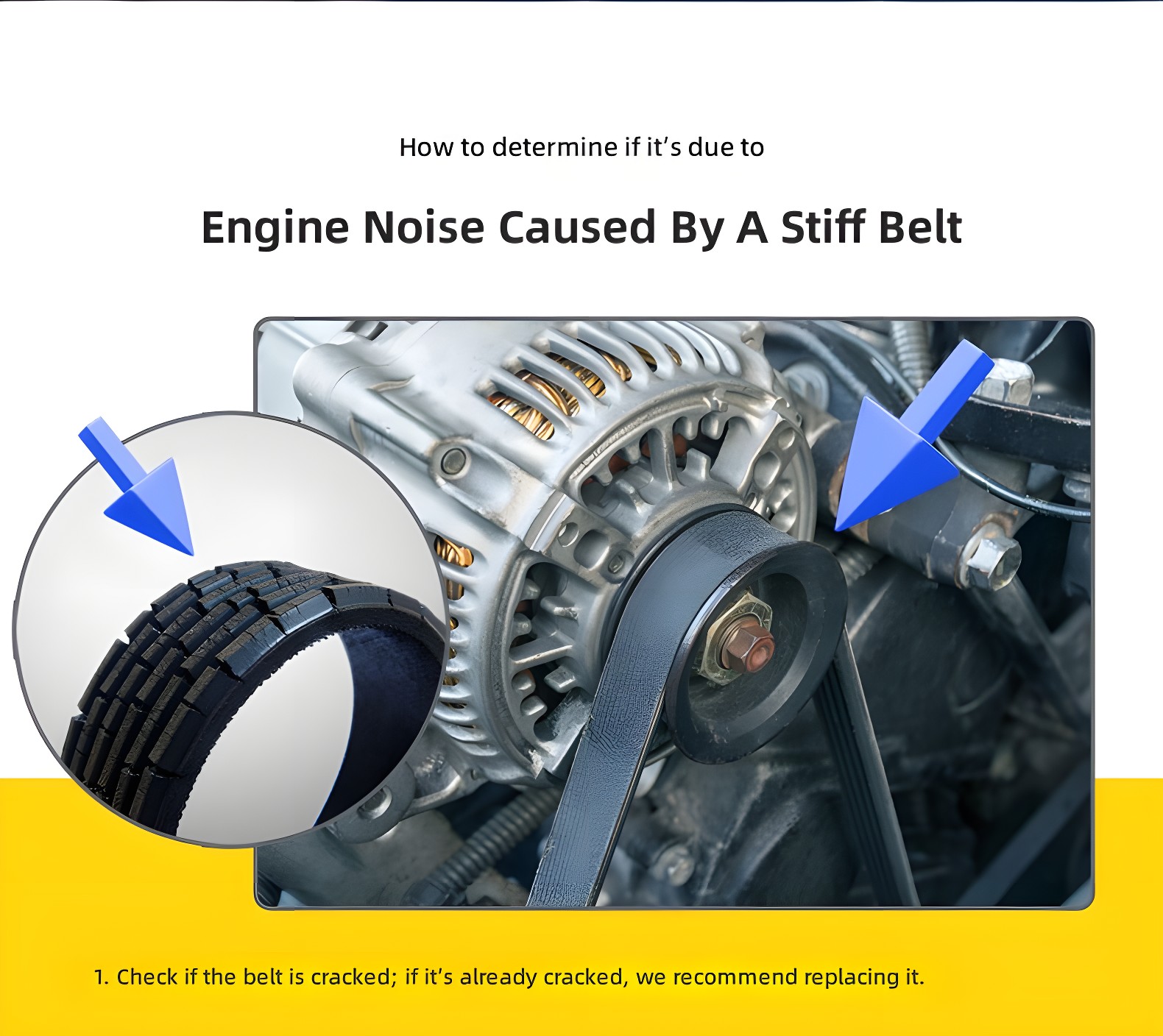

- Engine Belt Systems: Prevents belt hardening, cracking, and slippage by penetrating micro-fractures and restoring surface suppleness. Unlike oil-based sprays, it does not degrade rubber compounds or cause delamination.

- Sealing Components: Restores flexibility to weatherstripping, trunk seals, sunroof gaskets, and door edge trims—eliminating wind noise, water leaks, and premature wear.

- Brake & Suspension Hardware: Lubricates caliper slide pins, bushings, and pivot points without compromising braking efficiency or attracting brake dust.

- HVAC & Climate Control: Ensures smooth operation of blend doors, damper linkages, and actuator gears—critical for maintaining cabin comfort and system efficiency.

Industrial Reliability: Optimizing Machinery Uptime

In manufacturing, logistics, and infrastructure settings, unplanned downtime costs thousands per minute. WD-40 Specialist Silicone Lubricant delivers measurable ROI through preventive maintenance:

- Conveyor Systems: Reduces friction in roller bearings, chain guides, and tensioners—minimizing energy consumption and preventing belt misalignment.

- Pneumatic & Hydraulic Valves: Ensures precise actuation by lubricating O-rings, spools, and seals without causing swelling or leakage.

- Tool Maintenance: Extends the life of pneumatic tools, air grinders, and impact wrenches by protecting internal seals and vanes from dry-running damage.

- Electrical Enclosures: Safely lubricates latches, hinges, and locking mechanisms on control panels—preventing corrosion-induced seizing while maintaining IP ratings.

Household & Recreational Versatility

From garage workshops to backyard sheds, this product redefines everyday maintenance:

- Garage Door Openers: Eliminates noisy operation and jerky motion by treating rollers, tracks, and torsion springs.

- Window & Sliding Door Mechanisms: Restores effortless movement to jammed sashes and patio sliders—without staining frames or attracting dirt.

- Outdoor Equipment: Protects lawnmower deck linkages, bicycle suspension pivots, and boat hatch seals against saltwater corrosion and UV degradation.

- Consumer Electronics: Safely lubricates camera lens rings, printer paper feed rollers, and scanner mechanisms—where conductivity or residue would be catastrophic.

Diagnostic Clarity: Solving Real-World Problems

One of the most powerful attributes of WD-40 Specialist Silicone Lubricant is its diagnostic utility. When applied to suspected problem areas, it acts as both treatment and test:

- A persistent squeak that disappears after spraying indicates rubber or plastic component fatigue—not bearing failure.

- If a belt noise returns within minutes, the issue likely stems from misalignment or tension—not material degradation.

- In cases of intermittent electrical faults, lubricating connectors often resolves contact resistance issues caused by oxidation.

This capability empowers technicians, engineers, and DIY users alike to make informed decisions—avoiding unnecessary part replacements and optimizing maintenance intervals.

Scientific Validation & Compliance

WD-40 Specialist Silicone Lubricant meets rigorous international standards:

- RoHS Certified: Compliant with EU Directive 2011/65/EU, ensuring absence of hazardous substances (lead, mercury, cadmium, etc.).

- Non-Hazardous Classification: Classified as non-flammable (flash point > 100°C), non-toxic, and non-irritating under standard handling conditions.

- Material Compatibility Testing: Verified safe for use on aluminum, steel, stainless steel, brass, copper, ABS, polycarbonate, silicone rubber, neoprene, and EPDM—covering >95% of common engineering materials.

Each 360 mL aerosol can delivers approximately 180–200 precise sprays, with a fine mist nozzle enabling targeted application—even in confined spaces. The compact 200 mm × 66 mm dimensions ensure easy storage and portability, while the durable aluminum canister resists denting and puncture during transport.

Why Silicone Outperforms Traditional Lubricants

Many maintenance professionals still rely on mineral oils, lithium greases, or generic “multi-purpose” sprays. Yet these solutions present critical limitations:

| Parameter | Mineral Oil | Lithium Grease | WD-40 Specialist Silicone |

|---|---|---|---|

| Water Resistance | Poor (emulsifies) | Moderate (washes out) | Excellent (hydrophobic film) |

| Temperature Range | -20°C to +120°C | -30°C to +150°C | -50°C to +200°C |

| Electrical Safety | Conductive (risk of shorts) | Insulating but messy | Fully non-conductive |

| Material Compatibility | Swells rubber | Hardens plastics | Safe for elastomers & polymers |

| Cleanliness | Leaves oily residue | Attracts dust & debris | Dry, clean finish |

| Longevity | Days to weeks | Weeks to months | Months to years |

The data speaks unequivocally: silicone-based technology represents the future of precision lubrication—especially where reliability, cleanliness, and longevity are non-negotiable.

A Legacy of Trust, A Future of Innovation

WD-40’s 70-year journey—from NASA’s rocket assembly lines to today’s autonomous vehicle test benches—reflects an unwavering commitment to solving real-world mechanical challenges. The Specialist Silicone Lubricant is not merely another spray can; it is the culmination of decades of tribological research, field testing, and user feedback refinement.

Its formulation addresses the root causes of mechanical failure: friction-induced wear, environmental degradation, material incompatibility, and inadequate protection protocols. By integrating seamlessly into existing maintenance workflows—requiring no special tools, training, or disposal procedures—it lowers the barrier to professional-grade care while elevating overall system performance.

Whether you operate a fleet of commercial vehicles, manage a production line, maintain high-performance motorcycles, or simply wish to preserve your personal assets with scientific rigor—WD-40 Specialist Silicone Lubricant offers a universal solution grounded in proven engineering principles. It transforms routine maintenance from a reactive chore into a proactive strategy for asset preservation, operational continuity, and performance optimization.

In an era defined by complexity and interdependence, the simplest interventions often yield the greatest returns. One precise spray—applied correctly—can silence a grinding transmission, restore a seized hinge, prevent a catastrophic seal failure, or extend the life of a critical sensor by years. That is the power of intelligent lubrication. That is the promise of WD-40 Specialist Silicone Lubricant.

If you're interested in this product, please click View Product Details.