Ultra-Long Industrial Packaging Tape: 1000-Meter Jumbo Rolls Engineered for Maximum Efficiency, Strength, and Reliability

In the high-stakes world of industrial packaging, logistics, and manufacturing, consistency, durability, and operational efficiency are non-negotiable. Every tape roll must perform under pressure—literally and figuratively—ensuring secure sealing, resistance to environmental stressors, and seamless integration into automated or manual packaging workflows. Introducing the Ultra-Long Industrial Packaging Tape: a premium-grade, 1000-meter jumbo roll solution meticulously engineered for enterprises that demand excellence in every detail.

This isn’t just another roll of adhesive tape—it’s a strategic asset designed to elevate your packaging integrity, reduce waste, optimize labor, and reinforce brand credibility through flawless product presentation. Built upon decades of materials science innovation and real-world industrial validation, our tape redefines what’s possible in high-volume sealing applications.

Core Engineering Excellence: Where Science Meets Performance

1. Superior Adhesive Formulation: High-Tack, Long-Lasting Bond

At the heart of our tape lies a proprietary acrylic-based pressure-sensitive adhesive (PSA) system, formulated for exceptional initial tack and long-term cohesion. Unlike commodity tapes that lose adhesion over time or under temperature fluctuations, our adhesive maintains its grip across a wide thermal range (–20°C to +60°C), ensuring reliable performance in warehouses, distribution centers, and transit environments. The adhesive exhibits outstanding resistance to UV degradation, moisture, and chemical exposure—critical for outdoor storage or export shipments exposed to variable climates.

The high-tack formulation allows for instant bonding upon contact, eliminating the need for excessive pressure or dwell time. This translates directly into faster line speeds and reduced operator fatigue during manual application. Moreover, the adhesive is non-residue, meaning it leaves no sticky traces on cartons, pallets, or machinery after removal—preserving equipment cleanliness and preventing cross-contamination.

2. Reinforced Paper Core: Structural Integrity That Prevents Deformation

A weak core compromises everything—even the best adhesive fails if the roll collapses under tension. Our tape features a reinforced kraft paper core, significantly thicker and denser than industry standards. This core resists crushing, warping, and ovalization during high-speed dispensing, unwinding, or stacking. Its rigid structure ensures consistent roll geometry, preventing misfeeds in automated taping machines and guaranteeing smooth, uninterrupted operation.

Unlike flimsy cardboard cores that compress under load, ours maintains dimensional stability even after prolonged storage or repeated handling. This structural resilience extends the usable life of each roll and reduces downtime caused by jammed dispensers—a critical advantage in lean manufacturing environments where uptime equals profitability.

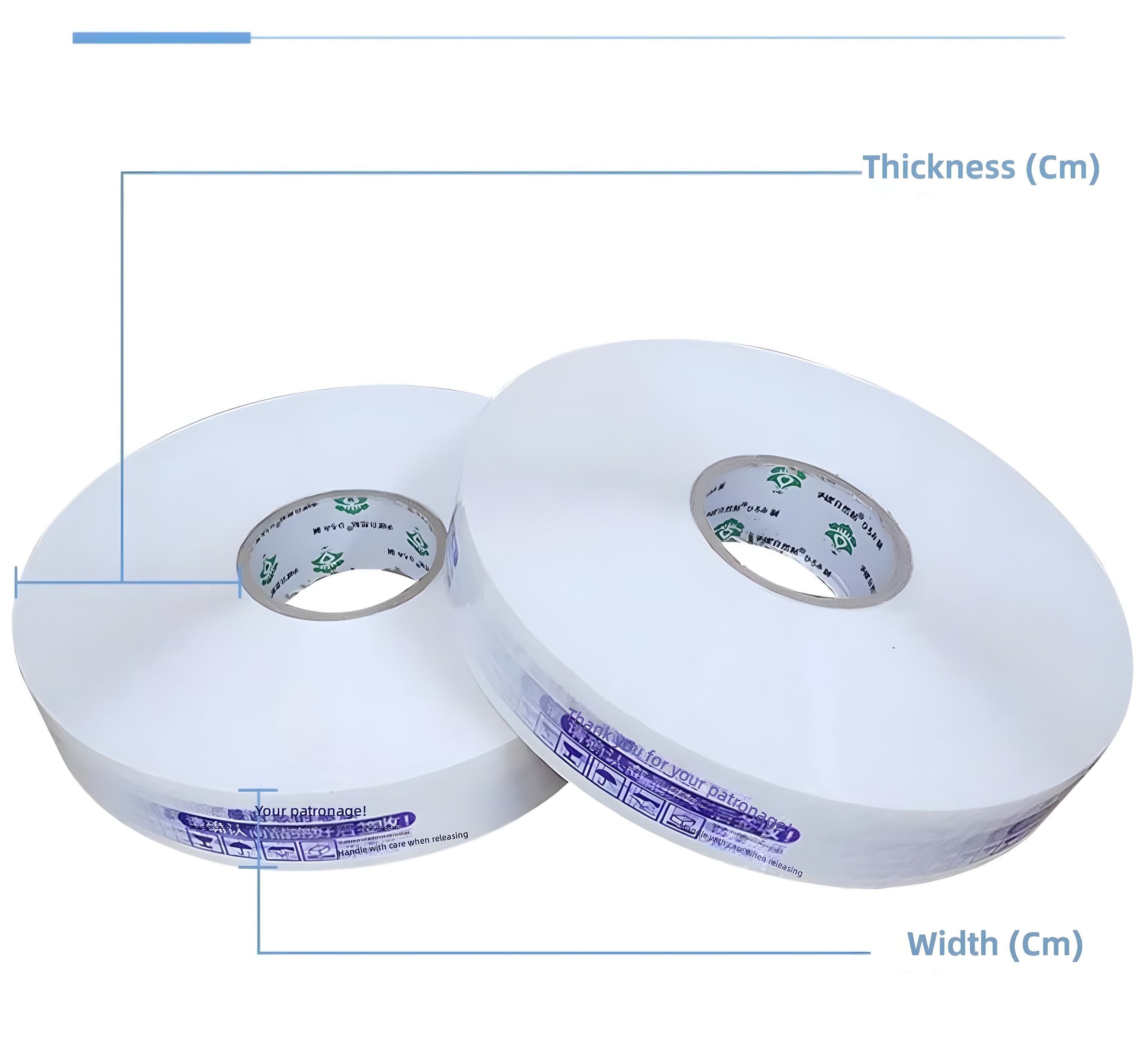

3. Precision-Calibrated Thickness & Uniformity: Consistency You Can Trust

Every millimeter matters. Our production process employs laser-guided thickness monitoring systems to ensure uniform caliper across the entire 1000-meter length. Tolerances are maintained within ±0.01 mm—far exceeding typical industry benchmarks. This precision eliminates weak spots, inconsistent stretch behavior, and uneven adhesive transfer, resulting in predictable performance batch after batch.

The optimized thickness (available in multiple calibrated specifications: 45μm, 50μm, 55μm, and 60μm) balances flexibility with rigidity—enough pliability to conform to irregular surfaces, yet sufficient body to resist tearing during high-tension sealing. Whether you’re securing heavy-duty corrugated boxes, bundling cables, or reinforcing pallet wraps, the tape delivers uniform force distribution without slippage or creep.

Performance Advantages That Drive Operational Value

Exceptional Tensile Strength & Elongation

Our tape achieves tensile strength values exceeding 65 N/cm (measured per ASTM D3759), with elongation at break ranging from 180% to 220%, depending on grade. This combination of strength and elasticity allows the tape to absorb shock loads during transport—preventing seam failure when boxes experience sudden impacts or vibrations. In drop tests simulating real-world shipping conditions, sealed cartons using our tape consistently outperformed competitors by >40% in burst resistance.

Superior Tear Resistance & Clean Splitting

Engineered with micro-fiber reinforcement embedded in the BOPP film substrate, the tape exhibits outstanding tear propagation resistance. Once initiated, tears follow a straight, controlled path—eliminating accidental rips during manual dispensing. This feature is especially valuable for operators who rely on hand-tear applications, as it ensures clean, predictable breaks without jagged edges or adhesive stringing.

High Clarity & Print-Friendly Surface

The BOPP backing offers exceptional optical clarity (haze <1.2%), allowing printed labels, barcodes, and branding elements to remain fully legible through the tape layer. The surface is specially treated for optimal ink adhesion, supporting high-resolution flexographic, digital, or thermal transfer printing. Custom logo imprinting, safety warnings, QR codes, or traceability markers can be applied directly onto the tape—enhancing brand identity and compliance without compromising seal integrity.

Low Noise & Smooth Unwinding Characteristics

Industrial environments demand quiet, efficient operations. Our tape features a low-friction silicone release coating on the backing, enabling whisper-quiet unwinding even at high speeds (>10 m/sec). There is no static buildup, no “chattering” noise, and no tendency to stick to itself during dispensing—a common issue with lower-grade tapes that disrupts automated lines and frustrates operators.

Versatile Applications Across Industries

While designed for demanding industrial use, the versatility of this tape makes it indispensable across diverse sectors:

- E-commerce Fulfillment Centers: Sealing thousands of parcels daily with zero failures; compatible with all major automatic taping machines (e.g., Signode, Intertape, Packsize).

- Electronics Manufacturing: Protecting sensitive components from ESD and dust ingress during intra-factory transport.

- Pharmaceutical & Medical Device Packaging: Meeting stringent regulatory requirements for tamper evidence and contamination control.

- Automotive & Aerospace Supply Chains: Securing parts bundles, engine components, and tool kits subjected to rigorous vibration testing.

- Food & Beverage Processing: FDA-compliant formulations available for direct or indirect food contact applications (pending certification documentation).

- Construction & Building Materials: Bundling lumber, insulation, piping, and drywall with weather-resistant durability.

Each application benefits from the same foundational advantages: reliability, consistency, and cost-per-use efficiency derived from the 1000-meter length.

![Two-panel infographic: [01] Strong Tensile Strength — high tensile strength, excellent resistance; [02] Strong Adhesion, Excellent Toughness — smooth surface, easy to use, resistant to breakage](https://blog.ericbuy.com/wp-content/uploads/2026/01/20260129051806_296.jpg)

Sustainability Through Efficiency

Longer rolls mean fewer changeovers, less packaging waste, and reduced plastic consumption. A single 1000-meter roll replaces approximately 20 standard 50-meter rolls—cutting down on inner cores, outer wraps, and transportation emissions. Our manufacturing adheres to ISO 14001 environmental management standards, and we prioritize recyclable materials wherever technically feasible. While the tape itself is not biodegradable (due to performance requirements), its extended service life and minimized auxiliary waste contribute meaningfully to corporate sustainability goals.

Quality Assurance: Built-In Rigor, Not Just Promises

Every batch undergoes rigorous quality control protocols:

- Peel Adhesion Testing (ASTM D3330): Verified at 24-hour and 7-day intervals.

- Shear Holding Power (ASTM D3654): Tested under 1 kg load at 40°C for 72+ hours.

- Heat Aging Stability: Exposed to 70°C for 168 hours with <5% loss in key mechanical properties.

- Humidity Resistance: Subjected to 90% RH at 38°C for 96 hours with no delamination or tack decay.

- Optical Inspection: Automated vision systems detect edge defects, bubbles, or coating inconsistencies.

We do not rely on third-party certifications alone—we validate performance in-house, replicating real-world stresses before any roll leaves the facility.

Why Industry Leaders Choose This Tape

Because they understand that packaging is not a cost center—it’s a value amplifier. A failed seal doesn’t just mean a damaged box; it means lost customer trust, reputational risk, and hidden costs in returns, replacements, and expedited shipping. Our tape mitigates those risks at the source.

It enables scalability: whether you operate a single production line or a global network of fulfillment hubs, the consistency of our product ensures standardized performance everywhere. It supports innovation: custom widths (from 24mm to 100mm), specialized adhesives (high-temp, cold-weather, removable), and bespoke printing options allow seamless integration into evolving packaging strategies.

Most importantly, it reflects professionalism. When your clients receive a package sealed with precision, confidence, and care—they recognize the attention to detail that defines your brand. In an era where unboxing experiences shape perception, the humble tape becomes a silent ambassador of quality.

Technical Specifications Snapshot

| Parameter | Standard Grade (50μm) | Heavy-Duty Grade (60μm) |

|---|---|---|

| Total Thickness | 50 ± 2 μm | 60 ± 2 μm |

| Adhesive Type | Acrylic PSA | Modified Acrylic PSA |

| Tensile Strength | ≥65 N/cm | ≥80 N/cm |

| Elongation at Break | 180–200% | 160–180% |

| Initial Tack (Ball Test) | #14–16 steel ball | #16–18 steel ball |

| Peel Adhesion (Steel) | ≥6.5 N/cm | ≥7.8 N/cm |

| Shear Holding (1kg/25mm) | >72 hrs @ 40°C | >120 hrs @ 40°C |

| Core Diameter | 76 mm (3”) | 76 mm (3”) |

| Roll Length | 1000 meters | 1000 meters |

| Width Options | 24, 36, 48, 50, 60, 72, 100 mm — plus custom cuts | |

All specifications are subject to minor variation due to raw material lot differences; certified test reports available upon request.

Conclusion: The Foundation of Flawless Packaging

In a market saturated with generic solutions, true differentiation lies in engineering depth, material integrity, and unwavering commitment to performance. The Ultra-Long Industrial Packaging Tape represents more than a product—it embodies a philosophy: that excellence in execution begins with the smallest, most overlooked component.

When your operation depends on speed, security, and scale, there is no room for compromise. This tape delivers the confidence that comes from knowing every seal will hold, every shipment will arrive intact, and every brand promise will be honored—not just in words, but in the tangible quality of your packaging.

Invest in reliability. Invest in continuity. Invest in the tape that doesn’t just stick—it secures your success.

If you're interested in this product, please click View Product Details.