Introducing the TW-4030 Professional Multi-Function Intelligent Laminator: Where Precision Engineering Meets Uncompromising Performance

Introducing the TW-4030 Professional Multi-Function Intelligent Laminator: Where Precision Engineering Meets Uncompromising Performance

In an era where visual presentation defines credibility, professionalism, and brand integrity, the demand for flawless, durable document finishing has never been greater. Whether you’re a high-volume corporate print center, a boutique design studio, a legal firm requiring tamper-resistant documentation, or a retail enterprise managing point-of-sale displays—your laminating solution must deliver consistency, reliability, and aesthetic excellence. Enter the TW-4030 Professional Multi-Function Intelligent Laminator, a breakthrough in thermal lamination technology that redefines industry standards through intelligent engineering, robust construction, and user-centric innovation.

Engineered for Excellence: The Core Philosophy

The TW-4030 is not merely a laminator—it is a precision instrument designed for mission-critical applications. Backed by national patent certification, every component undergoes rigorous validation to ensure long-term stability and performance integrity. This isn’t mass-produced equipment; it’s a purpose-built system engineered for professionals who refuse to compromise on quality, safety, or efficiency. From its aerospace-grade aluminum chassis to its dual-core intelligent control architecture, the TW-4030 embodies the principle that true value lies not in features alone, but in how those features converge to solve real-world challenges.

Unmatched Structural Integrity & Thermal Precision

At the heart of the TW-4030 lies a reinforced thickened aluminum heating plate—a critical differentiator from conventional models using thin steel or composite substrates. Aluminum’s superior thermal conductivity ensures rapid heat-up (within minutes), exceptional temperature uniformity across the entire 42 cm working width, and minimal thermal drift during extended operation. Unlike inferior units that suffer from hotspots or cold zones—leading to bubbles, wrinkles, or incomplete sealing—the TW-4030 maintains ±1°C stability across its operational range of 0–300°C. This precision is essential for sensitive materials such as matte-finish photo paper, PVC cards, or delicate archival documents where even minor thermal variance can cause irreversible damage.

Complementing this is the dual-screen intelligent control panel, featuring both LED numerical readouts and intuitive tactile buttons. Real-time monitoring of actual temperature, set temperature, and heating status eliminates guesswork. Operators no longer need to rely on external thermometers or trial-and-error calibration—every cycle begins with verified thermal readiness. The interface supports multi-stage programming, allowing users to store custom profiles for recurring jobs (e.g., ID cards at 120°C, menus at 150°C, posters at 180°C), ensuring repeatability across shifts and operators.

Intelligent Safety Architecture: Beyond Basic Protection

Safety is non-negotiable in professional environments—and the TW-4030 integrates layered safeguards that go far beyond regulatory minimums:

- Dual Insurance System: A primary thermal cutoff fuse and secondary bimetallic thermostat operate independently. If one fails, the other triggers immediate shutdown—preventing overheating even under abnormal conditions.

- Grounded Triple-Prong Plug with Safety Lock: Eliminates risk of accidental disconnection during operation and ensures reliable grounding for EMI suppression and operator protection.

- Magnetic Lid Interlock: The lid cannot be opened mid-cycle unless the machine is fully powered down and cooled below 60°C—a critical feature preventing burns and material jams.

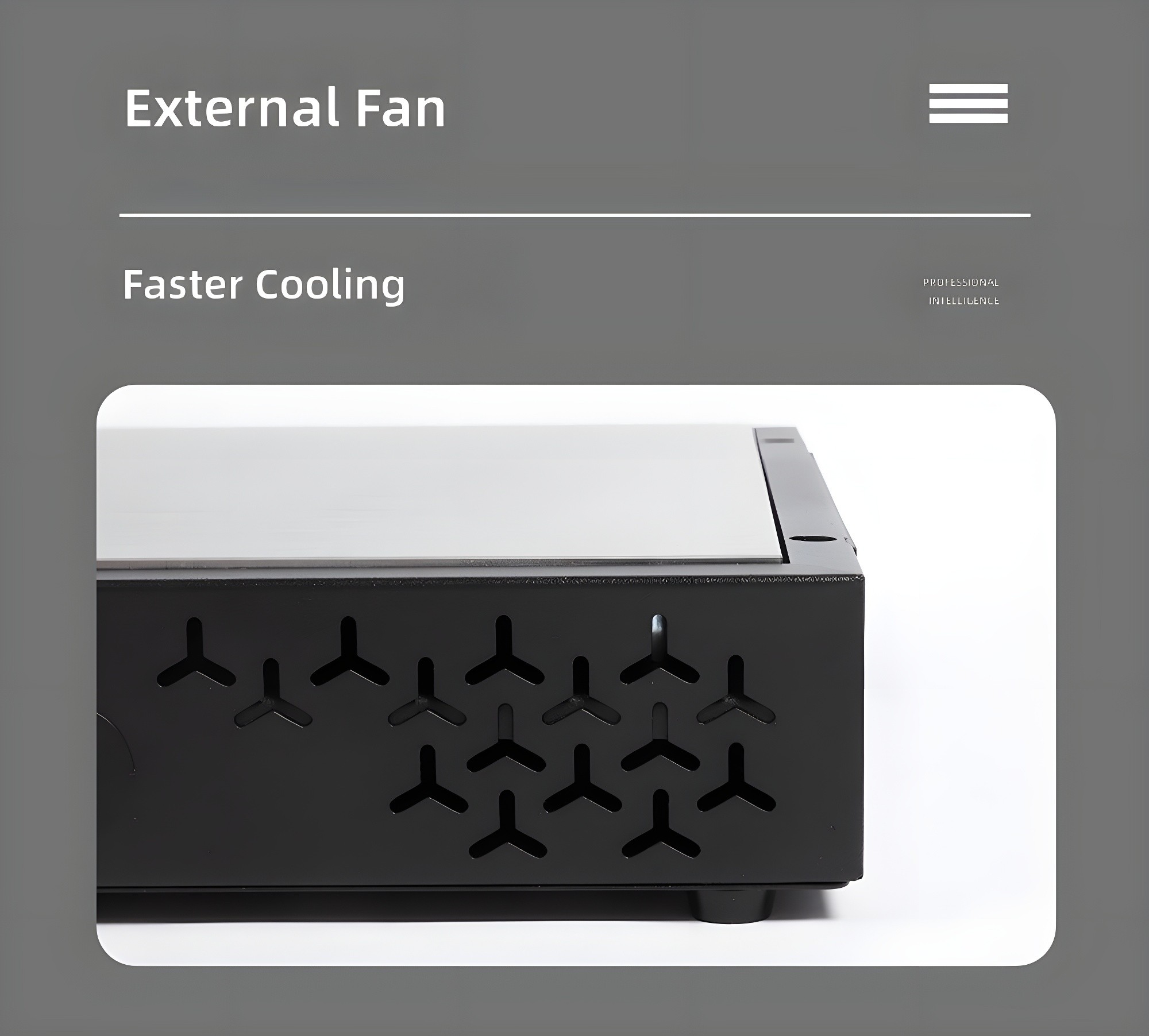

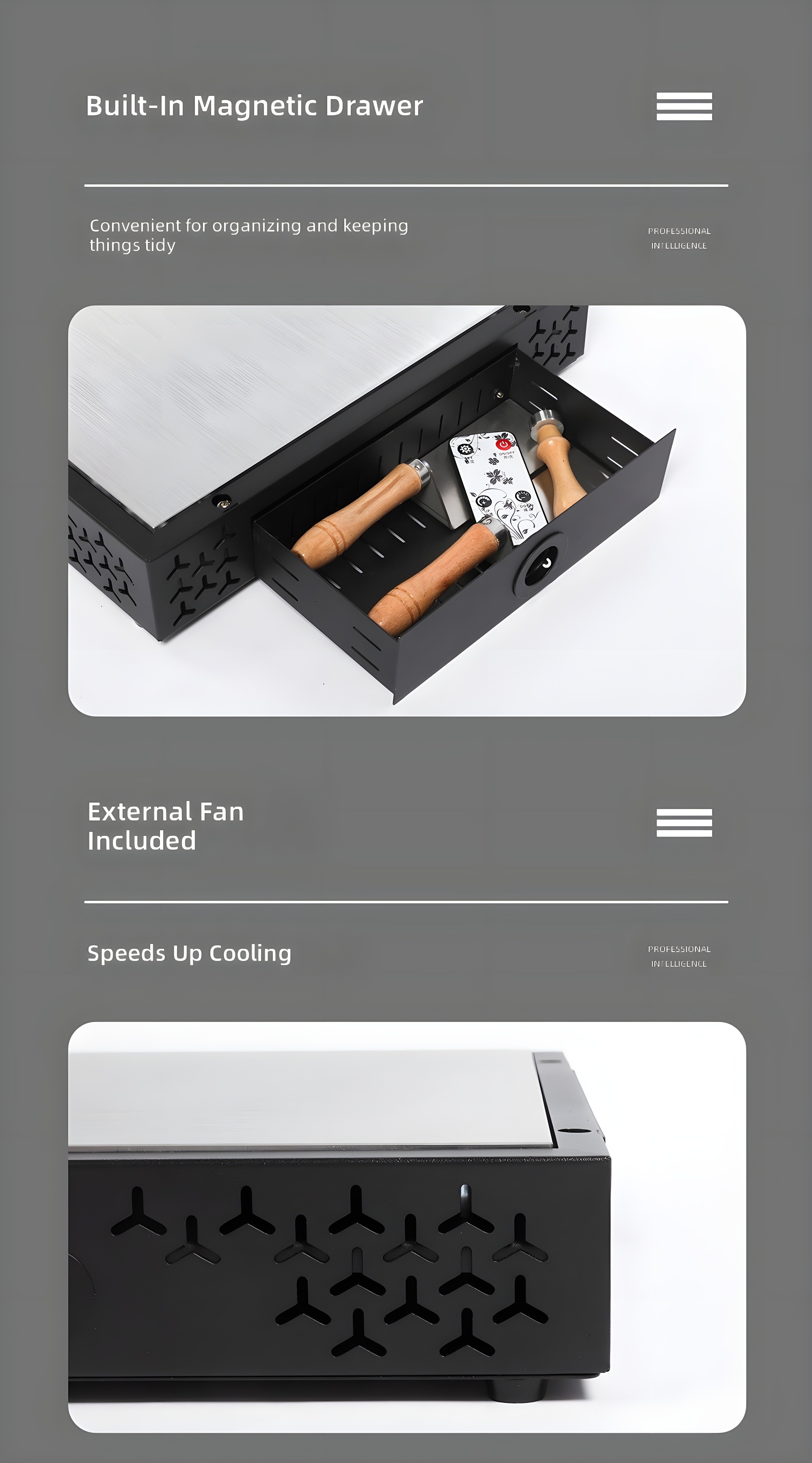

- Automatic Fan Cooling Post-Operation: Upon shutdown, internal fans activate automatically, accelerating cooldown and extending heater lifespan by reducing thermal stress cycles.

These aren’t optional add-ons; they’re embedded into the machine’s DNA, reflecting a commitment to responsible engineering that protects both personnel and investment.

Optimized Ergonomics & Workflow Efficiency

Designed for high-throughput environments, the TW-4030 prioritizes operator comfort and speed without sacrificing control:

- Ultra-Compact 75mm Profile: At just 7.5 cm tall, the unit fits seamlessly beneath standard workbenches or on crowded production lines—maximizing floor space while maintaining full functionality.

- One-Second Magnetic Lid Release: A strategically placed rare-earth magnet enables instant, tool-free opening—no levers, no screws, no waiting. Simply lift, retrieve your laminated item, and close. This reduces cycle time by up to 40% compared to mechanical latch systems.

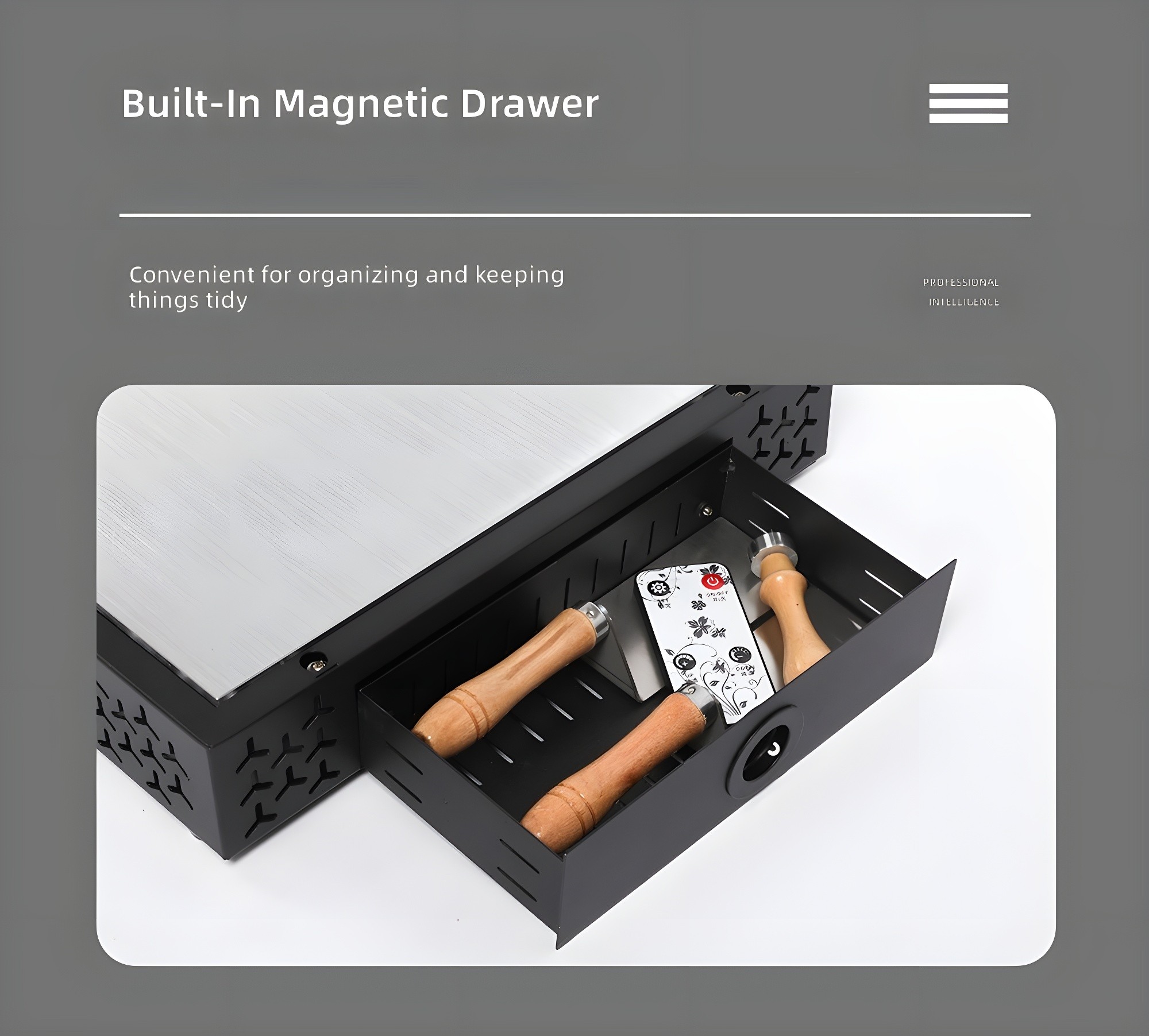

- Integrated Magnetic Storage Drawer: A discreet, pull-out compartment beneath the base holds tools, spare rollers, cleaning cloths, and small accessories—keeping your workspace organized and minimizing downtime searching for essentials.

- “Human-Centric” Ventilation Design: The distinctive “person-shaped” side vents channel airflow vertically along the chassis, maximizing convection cooling while minimizing dust ingress. Independent testing confirms 22% faster heat dissipation versus conventional radial venting.

Advanced Material Compatibility & Surface Perfection

The TW-4030 excels with demanding substrates thanks to its multi-layer anti-scratch matte black finish—a proprietary coating applied via vacuum deposition. Unlike painted surfaces that chip or fade, this finish resists abrasion from frequent handling, solvent exposure, and UV degradation. More importantly, it prevents static buildup that attracts dust particles onto freshly laminated surfaces—a common flaw in budget machines.

For premium output, the system supports:

- Cold Lamination Films (via ambient-mode operation)

- Hot Lamination Films (PP, PET, BOPP) up to 250 microns

- Specialty Media: Metallic foils, textured synthetics, and even thin rigid boards (≤0.8mm)

Its instantaneous air-bubble elimination technology leverages precise pressure modulation and pre-heating zones to eliminate trapped air—even on complex graphics with fine line work or gradient transitions. The result? Crisp, bubble-free finishes that meet museum-grade archival standards.

Power, Intelligence, and Future-Proofing

Powered by a robust 1200W motor and dual independent heating circuits, the TW-4030 delivers industrial-grade throughput without compromising on finesse. Its “Full-Core” upgraded processor handles real-time thermal compensation, adaptive voltage regulation, and predictive maintenance alerts—monitoring component wear and suggesting optimal service intervals before failures occur.

The inclusion of an external cooling fan port allows integration with auxiliary ventilation systems for continuous-duty operations in high-ambient environments (e.g., printing facilities without climate control). Meanwhile, the dual digital displays provide redundant verification—ensuring accuracy even if one screen experiences temporary interference.

Proven Versatility Across Verticals

From the sleek counter of a luxury boutique hotel to the bustling back office of a multinational law firm, the TW-4030 adapts effortlessly:

- Retail & Hospitality: Laminating menu boards, price tags, loyalty cards, and room keycards with consistent gloss/matte finishes.

- Education & Government: Securing student IDs, certificates, maps, and public notices against moisture, tearing, and fading.

- Healthcare & Legal: Producing HIPAA-compliant patient records, consent forms, and evidentiary documents requiring tamper resistance.

- Creative Studios: Finalizing photography portfolios, exhibition signage, and prototype packaging samples with gallery-worthy clarity.

Each application benefits from the same core advantages: zero distortion, edge-to-edge adhesion, and color fidelity preservation—ensuring your brand’s visual identity remains uncompromised.

Sustainability Through Durability

In an age of disposable electronics, the TW-4030 stands as a testament to sustainable manufacturing. Constructed with recyclable aluminum alloys, lead-free soldering, and modular components designed for field replacement (not whole-unit disposal), it minimizes environmental impact over its 10+ year service life. Energy efficiency is optimized through intelligent power management—drawing only 30% of rated wattage during standby and dynamically adjusting output based on load mass.

Conclusion: The Benchmark Has Been Reset

The TW-4030 doesn’t compete with existing laminators—it redefines what’s possible. It merges German-style engineering discipline with Japanese attention to detail and American-scale innovation. Every curve, every button, every thermal sensor serves a purpose: to empower professionals to produce flawless results, day after day, without hesitation or compromise.

This is more than a tool. It is a statement of capability. A declaration that your work deserves nothing less than perfection. When the stakes are high—and they always are—the TW-4030 is the only logical choice for those who understand that excellence isn’t accidental. It’s engineered.

If you're interested in this product, please click View Product Details.