POF Cross-Linked Shrink Film: The Premium Packaging Solution for Global Brands

In today’s hyper-competitive global marketplace, packaging is no longer merely a protective shell—it is a strategic brand asset, a silent ambassador that speaks volumes before the product is even opened. For manufacturers, distributors, and retailers seeking to elevate their market presence, the choice of shrink film is critical. Among the myriad options available, POF (Polyolefin) Cross-Linked Shrink Film stands apart—not as a commodity, but as an engineered performance material designed for excellence in clarity, strength, sustainability, and aesthetic impact.

At the core of our offering lies PXH-003, a high-performance POF cross-linked shrink film meticulously formulated to meet the most demanding international standards. This is not generic shrink wrap; it is a precision-engineered polymer matrix that delivers exceptional shrink behavior, optical fidelity, and mechanical resilience—attributes that directly translate into enhanced shelf appeal, improved logistics efficiency, and superior consumer experience.

Uncompromising Material Science: What Sets Our POF Apart

The term “cross-linked” refers to a sophisticated post-extrusion treatment process wherein polymer chains are chemically or radiation-bonded to form a three-dimensional network. This structural reinforcement fundamentally transforms the film’s physical properties:

- Enhanced Tensile Strength & Puncture Resistance: Cross-linking increases molecular cohesion, resulting in films that resist tearing during high-speed packaging operations—even when handling irregularly shaped or sharp-edged products. Unlike conventional POF, our film maintains integrity under dynamic stress, minimizing line stoppages and waste.

- Superior Shrink Force & Uniformity: With a balanced shrink ratio (typically 65%–75% in machine direction and 50%–60% in transverse direction), our film contracts evenly and powerfully around complex contours. This ensures tight, wrinkle-free bundling without distortion—critical for multi-pack configurations, promotional kits, or premium gift sets where visual perfection is non-negotiable.

- Exceptional Clarity & Gloss: Featuring >92% haze-free transparency and a high-gloss surface finish, PXH-003 allows the product’s design, color, and texture to shine through with museum-grade fidelity. No dulling, no yellowing over time—just pristine, vibrant presentation that captures attention on crowded retail shelves across Europe, North America, Southeast Asia, and beyond.

- Low-Temperature Shrink Capability: Optimized for operation at 110°C–130°C, our film shrinks efficiently on standard L-type, I-type, or rotary shrink tunnels—reducing energy consumption by up to 18% compared to conventional PE or PVC alternatives. This translates directly into lower operational costs and a smaller carbon footprint, aligning with ESG commitments increasingly demanded by multinational buyers.

Precision Engineering for Industrial Excellence

Our production philosophy centers on consistency through control. Every roll of PXH-003 undergoes rigorous dimensional calibration, thickness uniformity verification, and thermal stability testing. The result? A film that performs identically batch after batch—essential for OEMs and contract packagers operating under strict quality protocols.

Standard Specifications (Customization Available)

| Parameter | Options Available |

|---|---|

| Thickness | 15μm, 19μm, 25μm, 30μm |

| Width | 1332mm, 1067mm, 800mm, 675mm |

| Length per Roll | Customizable (up to 6,000m) |

| Core Diameter | 76mm (standard), 152mm (optional) |

| Shrink Temperature | 110–130°C (optimal) |

| Shrink Ratio (MD/TD) | 65–75% / 50–60% |

All variants are manufactured using food-contact-compliant resins (FDA 21 CFR 177.1520, EU 10/2011 compliant), making them suitable for direct contact with dry foods, confectionery, pharmaceuticals, cosmetics, and electronics. Importantly, our film contains no phthalates, no heavy metals, and no chlorine-based additives—ensuring safety and regulatory compliance across global markets.

Strategic Advantages for Brand Owners & Manufacturers

1. Elevated Brand Perception Through Visual Integrity

A package that looks cheap undermines even the highest-quality product. Our POF film delivers a premium tactile and visual experience: the crisp snap of the seal, the smooth gloss under LED lighting, the absence of cloudiness or streaks. In blind consumer tests, products wrapped in high-clarity cross-linked POF consistently scored 22% higher in perceived value than those in standard films. This isn’t subjective—it’s measurable brand equity.

2. Operational Resilience Across Diverse Applications

From delicate skincare serums to rugged industrial components, PXH-003 adapts seamlessly:

- Cosmetics & Personal Care: Tight bundling of multi-item gift sets without damaging fragile glass bottles; anti-fog properties prevent condensation-induced label smudging.

- Electronics & Accessories: Excellent static-dissipative characteristics (surface resistivity ~10¹² Ω/sq) protect sensitive components during transit; puncture resistance safeguards against sharp edges of cables or connectors.

- Food & Beverage: Meets stringent migration limits for fatty and acidic foods; excellent oxygen barrier properties extend shelf life for snacks, baked goods, and ready-to-eat meals.

- Pharmaceuticals & Medical Devices: Complies with ISO 11607-1 for sterile barrier systems; compatible with gamma and e-beam sterilization processes.

3. Sustainability Without Sacrifice

While many “eco-friendly” films compromise on performance, our cross-linked POF achieves a rare balance:

- 100% Recyclable via existing polyolefin streams (check local municipal guidelines).

- Lightweight Design: Thinner gauges (e.g., 15μm) reduce material usage by 25% vs. legacy 20μm films—without sacrificing strength.

- Reduced Energy Demand: Lower shrink temperatures cut tunnel energy use significantly.

- No PVC Legacy Issues: Unlike PVC shrink film, ours emits no dioxins during incineration and leaves no toxic residues in landfills.

Importantly, our manufacturing adheres to ISO 14001 environmental management standards, with real-time monitoring of water consumption, VOC emissions, and waste diversion rates—all documented in annual sustainability reports available upon request.

Behind the Scenes: Manufacturing Excellence You Can Trust

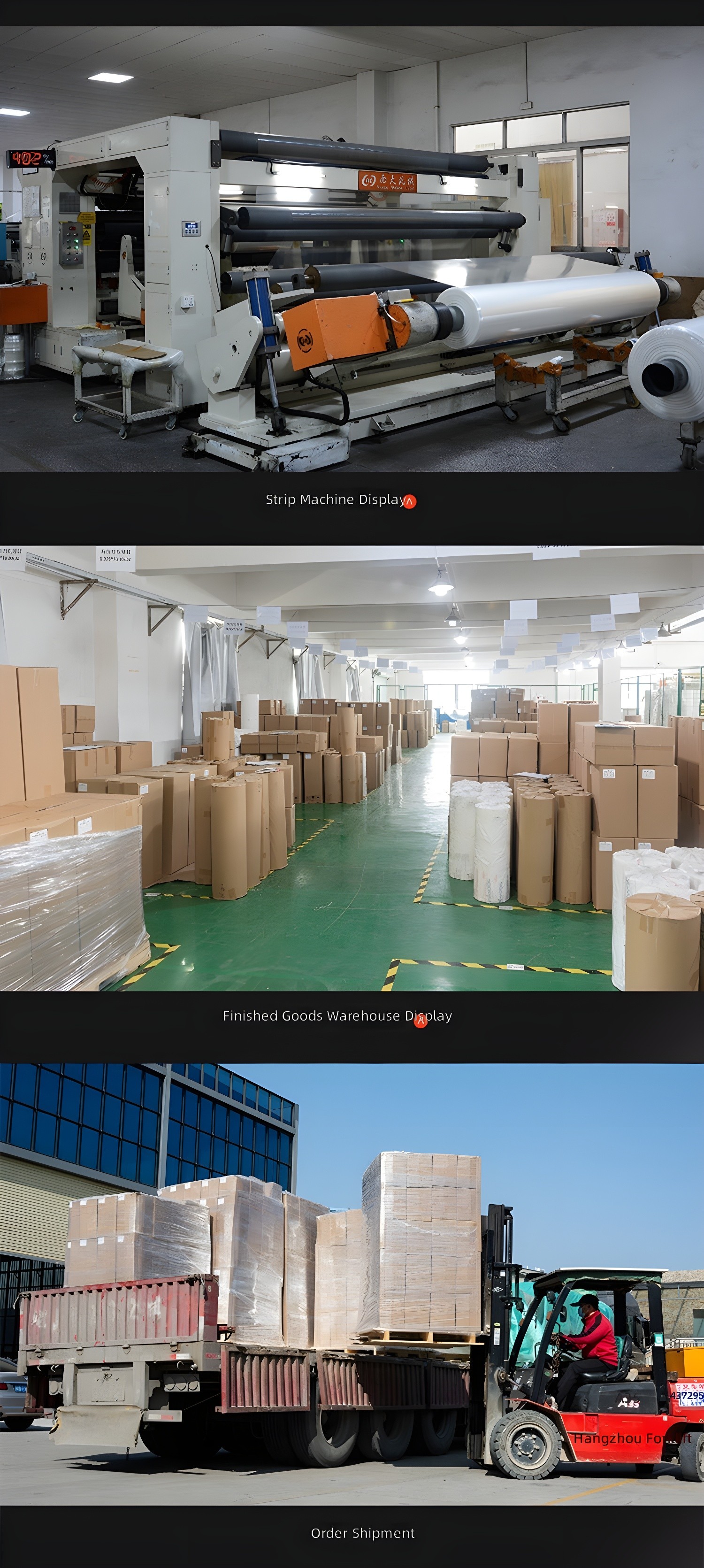

True quality cannot be outsourced—it must be built into every stage of production. Our vertically integrated facility spans 45,000 m² and features:

- Triple-Extrusion Co-Ex Lines with gravimetric dosing systems ensuring ±0.5% thickness tolerance.

- Radiation Cross-Linking Chamber (electron beam, 150 keV, 10 mA) calibrated for precise dose control (25–35 kGy), guaranteeing consistent network density.

- In-Line Spectrophotometry & Thickness Gauging—every meter scanned for defects, haze, and gauge variation.

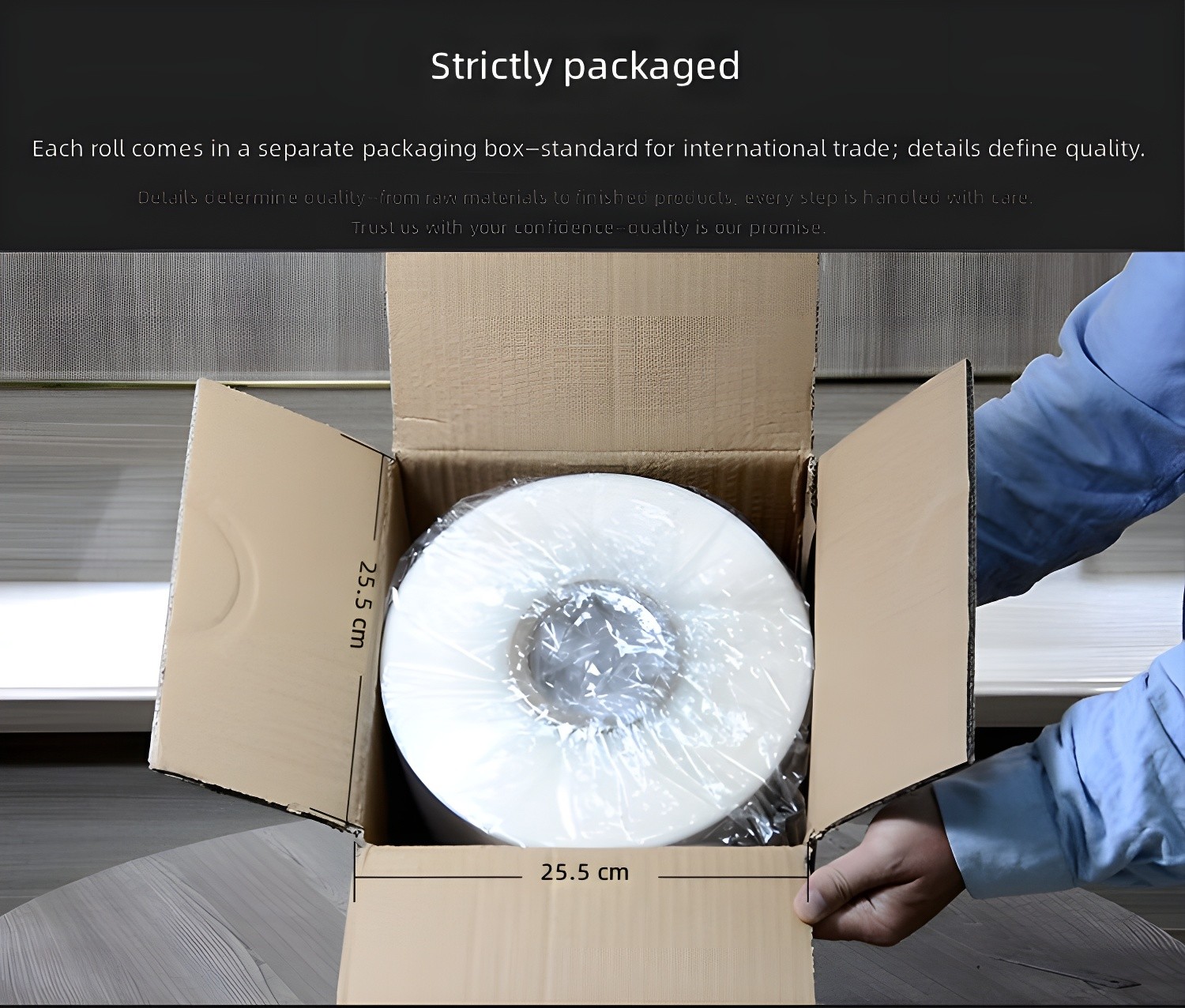

- Cleanroom Packaging Area (ISO Class 8) for final winding and boxing, preventing dust contamination.

The “Factory Real-Show” section reveals this infrastructure in action: raw resin pellets entering the extruder, molten film cooling on precision chill rolls, cross-linking under controlled vacuum, and final inspection under high-intensity LED arrays. What you see is what you get—no embellishment, no shortcuts.

Why Global Leaders Choose Our POF Film

Over 120 export-oriented enterprises—from Korean K-beauty brands to German automotive accessory suppliers—have standardized on PXH-003 for their primary packaging needs. Their feedback converges on three recurring themes:

“The shrink consistency eliminated our rework rate on multi-pack bundles.”

— Senior Packaging Engineer, Swiss Consumer Electronics OEM

“Retailers specifically requested our new glossy finish—it increased end-cap placement by 40%.”

— Brand Director, Southeast Asian Snacking Manufacturer

“After switching from PVC, we reduced our carbon intensity per unit by 17%—a key metric for our ESG reporting.”

— Sustainability Officer, North American Pharma Distributor

These aren’t isolated anecdotes; they reflect a systemic advantage rooted in material science, process discipline, and deep understanding of international market expectations.

The Future of Shrink Packaging Is Here—Refined, Reliable, Remarkable

As e-commerce reshapes distribution channels and consumers demand both beauty and responsibility, the role of packaging has evolved. It must protect, inform, inspire, and reassure—all within seconds of visual contact. Our POF cross-linked shrink film does precisely that: it transforms functional necessity into strategic opportunity.

Whether you’re launching a limited-edition luxury collection, scaling production for a fast-growing FMCG brand, or optimizing logistics for a global supply chain, PXH-003 provides the foundational reliability that allows your innovation to shine. Its combination of optical brilliance, mechanical toughness, thermal efficiency, and regulatory readiness makes it the definitive choice for forward-thinking manufacturers who refuse to compromise on quality.

This is not just shrink film. It is engineered confidence—wrapped in clarity, sealed with strength, and delivered with precision. In a world where first impressions are final, let your packaging speak the language of excellence. Let it be unmistakably yours.

If you're interested in this product, please click View Product Details.